Purpose: Improved efficiency of wood chip boiler through condensation

In November 2016, SEG A/S delivered, installed and commissioned a new 5G3MC absorption heat pump with a cooling capacity of 900 kW. On the cooling side of the heat pump, cold water is supplied to the flue gas scrubber, which cools down the chimney temperature to close to 18°C, thus absorbing and recovering the condensation heat from the flue gases. This recovered energy is returned to the district heating water on the condenser and absorber side, preheating the district heating return water before it enters the boilers. This raises the total power output of the boiler.

The driving energy for the heat pump generator is supplied by the wood chip boiler at a temperature of around 115°C.

The evaporator tubes, end plates and reversing chambers of the chiller are made of stainless steel to withstand the effects of scrubber water.

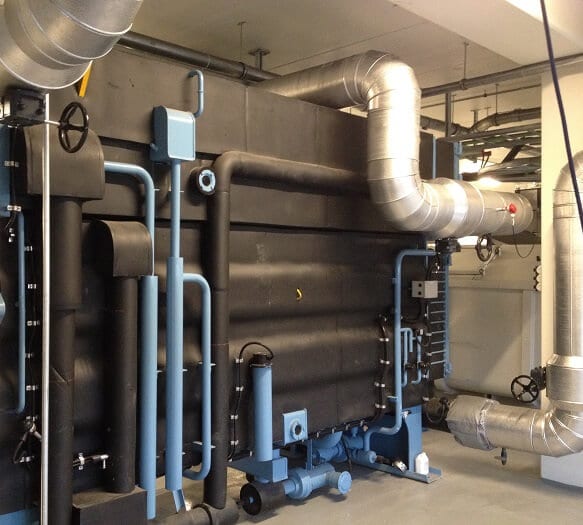

The design of this type of Thermax heat pump is different from those delivered so far. The machine has become more compact with its square shapes. It is still a single effect driven generator, but the lower part evaporator is divided into two chambers called "twin design". The design allows the evaporators to have different temperature levels, cooling the water in two stages. This allows the highest concentration of brine from the hottest generator to cool the output of the low temperature evaporator better.

If you want to read more about the new design, you can find information here: