Purpose: Improved efficiency of wood chip boiler

With this project, SEG A/S designed, delivered and commissioned a turn-key solution consisting of:

Flue gas scrubber for cooling flue gases to around 15°C.

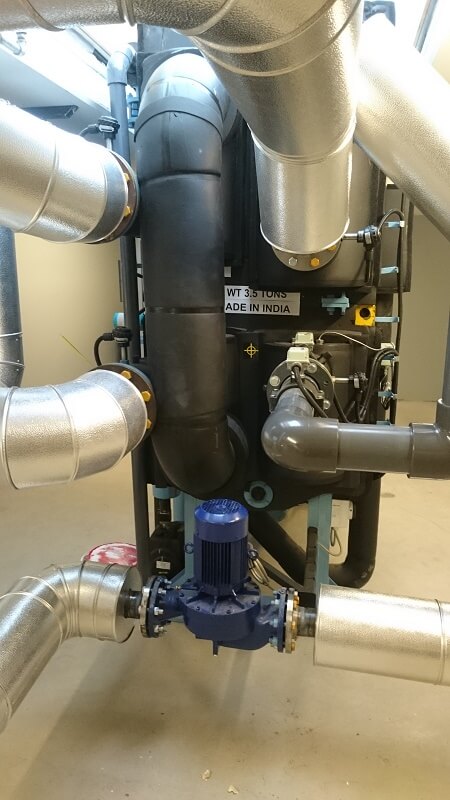

Thermax LT10C absorption heat pump with a cooling capacity of 300 kW

Piping connections and pumps

The chip boiler supplies driving heat to the chiller generator at a temperature of around 114°C. The scrubber circuit from the flue scrubber is led directly through the chiller's evaporator circuit, where the scrubber water is cooled down to around 12°C. The cooling machine's evaporator tubes, end plates and reversing chambers are made of stainless steel to withstand the effects of the scrubber water. The chimney temperature is lowered to close to 12°C, utilizing the heat of condensation from the flue gas to increase the overall efficiency of the plant. The chiller has been in operation since June 2015.